Maintenance & repair services

Investing in a Tolerans stitching solution provides access to a complete service program tailored to suit each customer’s needs for preventive maintenance and repair actions including remote support.

We offer several types of service contract where our service technicians make one or more visits per year for preventative maintenance and machine cleaning. We also replace specified wear parts and test run the stitcher in the press at full production speed. If you use stitching frequently, we can design a service contract that best suits your needs.

Maintenance instructions

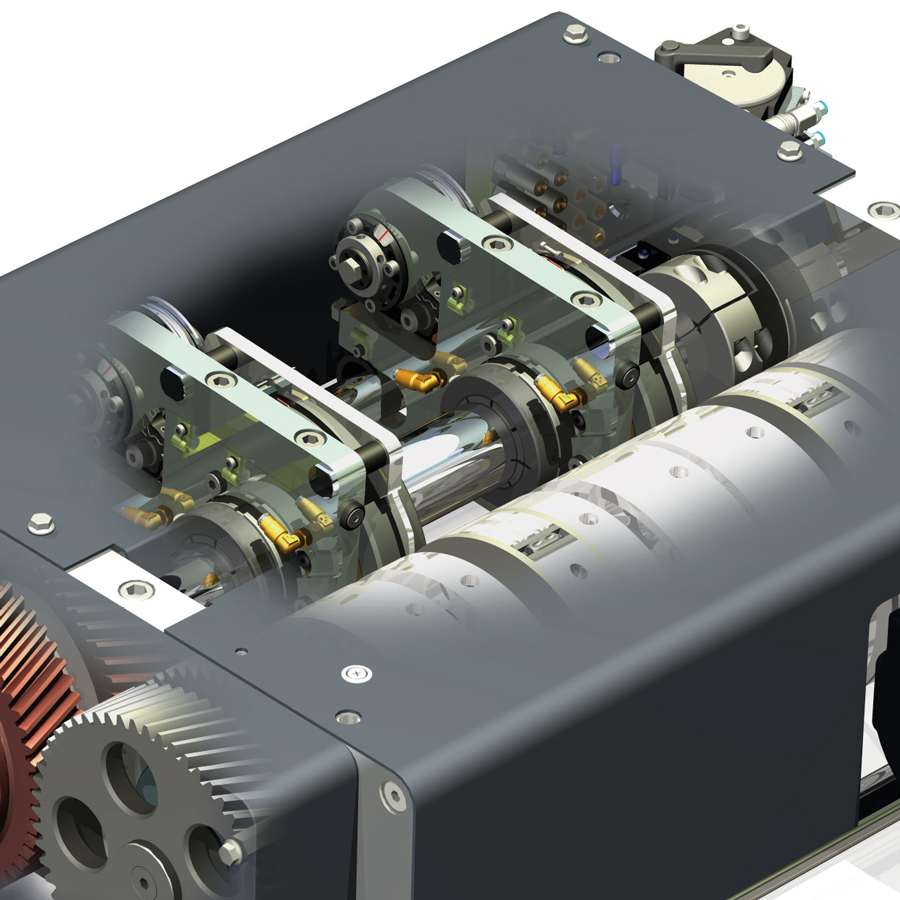

The function and high-performance of our machines are dependent upon proper maintenance, some of which the customer can perform. In order to make maintenance easier and procedures simple to understand, Tolerans machines are supplied with detailed maintenance manuals. To further clarify the various procedures, we’ve created videos and animations, which can be seen here.

Instruction Videos

| 00. Changing the catch fork How to change the only moving part – the catch fork. |

01. Changing the wire rest Easy changing procedure. |

02. Change of side plate Change of the black side plates on the stitching cylinders. |

|

|

||

| 03. Changing the horn The hardened metal horn on top of each stitching cylinder. |

04. Disconnecting & connecting the feedbox Basic instructions. |

05. Changing the timing belt Easy description. |

|

|

||

| 06. Undoing the belt pulley Instruction and important notice. |

07. Feedbox dismantling and cleaning Keep zink and paper dust out of the feed box. |

08. Adjusting the former wheel To get the correct u-shape of the staple. |

|

|

||

| 09. Adjusting the catch of the wire Important to get a good staple and minimize wear on fork and wire rest. |

10. Anvil(clincher die) adjustment Instruction for ribbon stitcher that also can be used for cylinder stitcher. |

|